Refractory Zirmul Bricks for glass furnaces

Model Number:

Certification:

Minimum Order Quantity:

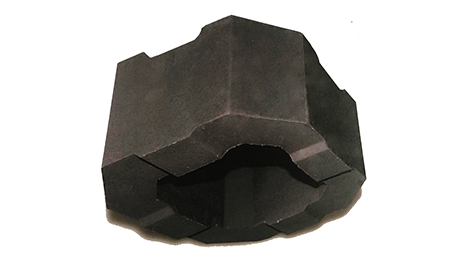

Zircon diamond stone bricks is made by the zircon ore as raw material, adding a small amount of plastic clay, mixing, compacting and calcined into clumps. The lump is then crushed and added a small amount of plastic clay or other organic binders and mixed, shaped, and burned. Calcination and firing temperature should not exceed 1600 degrees, generally can be done by 1400 hours under a long time insulation to burn.

Zircon diamond stone brickss, a kind of shaped refractory brick, are manufactured with stable zircon sand and over 64% zircon content. Zircon diamond stone bricks belongs to acid refractory material with various properties of high mechanical strength, good thermal shock resistance, high refractoriness under load, strong erosion resistance and high density and etc. Zircon diamond stone brickss can be widely used in glass furnace, Ladle, pure steel furnace, non-ferrous metal smelting furnace and so on.

Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients' quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Typical Features:

1. Low porosity, high compressive strength, flexural strength of high pressure, good bulk stability;

2. Good thermal shock resistance, anti-spalling

3. Easy-to-skin hanging in the kiln, and low thermal conductivity;

4. High temperature of refractoriness under load.

5. Ultra-high-temperature firing, high direct binding rate, high refractoriness and corrosion resistance.

6. Strong resistance against alkaline substances, the acid resistance better than the magnesia refractories.

Zircon diamond stone brickss | ||||||

| Item/Index | ZR-30 | ZR-50 | ZR-55 | ZR-60 | ZR-62 | |

| Al2O3 % | 42 | 10 | 6 | 4 | – | |

| SiO2 | 20 | 34 | 35 | 30 | 34 | |

| ZrO2 | 30 | 50 | 55 | 60 | 62 | |

| Bulk Density (g/cm3) | ≥3.10 | ≥3.30 | ≥3.45 | ≥3.50 | ≥3.60 | |

| Apparent Porosity % | ≤21 | ≤20 | ≤20 | ≤21 | ≤20 | |

| Compressive Strength (kg/cm2) | ≥500 | ≥400 | ≥500 | ≥500 | ≥500 | |

| Refractoriness Under Load ℃ (T2) | >1500 | >1450 | >1500 | >1600 | >1550 | |

| Expansion at 1000℃ (%) | 0.6~0.8 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | |

| Thermal Conductivity | 500℃ | 1.7 | 1.4 | 1.3 | 1.2 | 1.2 |

| 1000℃ | 1.8 | 1.6 | 1.5 | 1.5 | 1.5 | |

| Application | Glass Furnace | Nozzle Seat | Ladle | Ladle | Ladle Glass Furnace | |

Application:

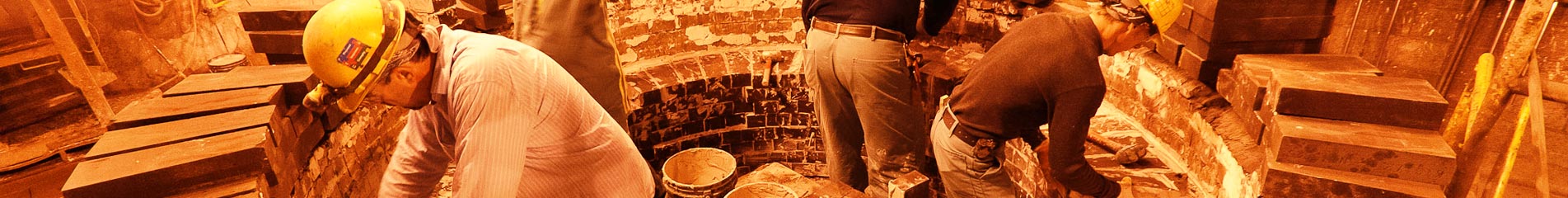

They are used for high temperature equipment in the glass furnace, molten steel ladle and continual casting water month.

Some of the products mainly used in glass contact portion of alkali free or low-alkali glass melting furnace, especially some special region of glass tank, such as paving part and secondary layer of paving bottom, wall and bottom of fore hearth, flowing spout and spinning portion and melter, back lining of fore hearth, and also used in lining of other quality glass furnace and special glass furnace with high corrosion resistance, such as boron silicate glass, ceramic glass, low-alkali or other technical glass

Some of other products are used in upper area of flame space or frequent thermal shock region of alkali-free or low-alkali glass, sodium-calcium glass, boron-silicate glass, lead glass and other technical glass melting furnace, such as transition region between up roof silica brick and fusion zirconia-corundum brick or fusion zirconia-mullite brick, transition region between silica brick and magnesia brick, crown, burner, thermal couple, peep hole, secondary layer of melter bottom and its back its back lining, and also used in ladle lining for metallurgical industry

Glass melting furnace.

Ladle lining in the metallurgical industry.

Areas of crown, burner, thermal couple, peep hole, and secondary layer of melter bottom and back lining.

Areas of glass tank, such as paving part and secondary layer of paving bottom, back lining, wall and bottom of fore hearth, flowing spout and spinning portion and melter.

Upper area of flame space or frequent thermal shock position.

Lining of alkali-free or low-alkali glass, sodium-calcium glass, boron-silicate glass, ceramic glass, lead glass, and other technical glass melting furnace.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

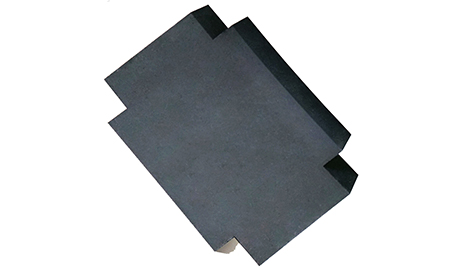

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..