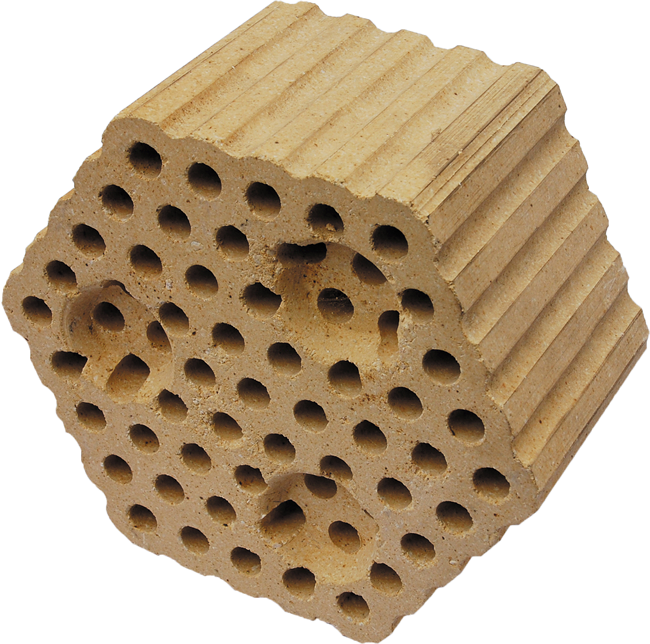

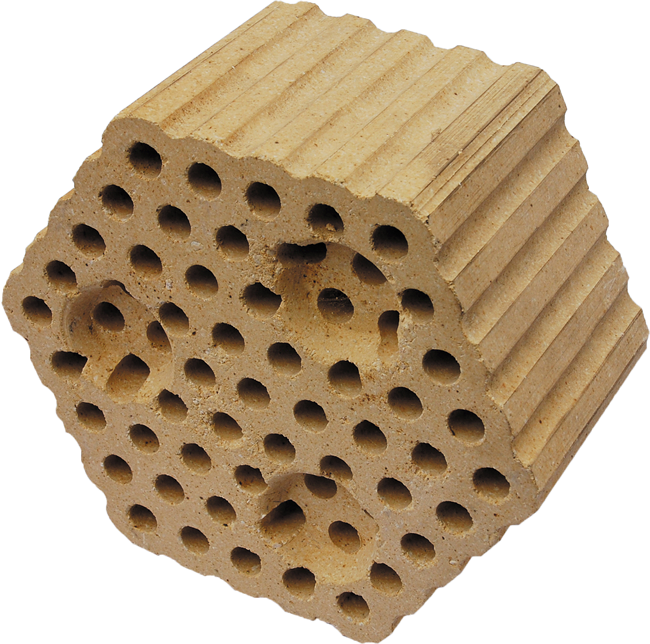

High Alumina Checker brick for Hot Blast Stove

2021-04-15 03:04:05

Checker brick is widely recognized and accepted by the world ironmaking industry. It is a kind of excellent thermal characteristics heat accumulator with characteristics of strong heat exchange capacity, large heat storage area, smooth ventilation, and small resistance. Checker brick is a heat transfer medium. It is applied in the regenerator of blast furnace hot blast stove, usually ordered arrangement in the regenerator, and it plays a role of heat storage during the burning period. During the “air supply period”, the cold air is heated into hot air through convection heat exchange and radiant heat exchange.

Characteristics:

- It has a plurality of open lattice holes parallel to the side surface, as well as the positioning bulge and positioning grooves on the two parallel surfaces.

- High volume stability, high load creep performance, high density, and low porosity. The modern blast furnace of blast furnace usually adopts the structure of the lattice brick regenerator.

At present, checker bricks are mainly used in the blast furnace hot blast stove, and flame furnace.

The checker brick is mainly used in the regenerator of the hot blast stove. The checker brick with a certain checkerwork cell is arranged in order, and the upper and lower holes of the checker brick can be allowed to pass through the gas. According to the technology requirements of different temperature areas, generally select siliceous checker brick, clay brick, in some blast furnace, also have the option of high alumina brick, mullite bricks, sillimanite brick.ect.

Relevant information

-

Thermal storage alumina balls

The Thermal storage alumina ballsis made of industrial alumina and refractory kaolin as the main raw materials through scientific formula, forming and high-temperature calcination.Thermal storage alumina ballss are divid··· -

Anti-stripping high alumina brick

Use description of Anti-stripping high alumina brick1. Anti-stripping high alumina brick has a good application in low temperature parts such as large and medium-sized cement precalciner, kiln smoke chamber, indoor decom··· -

Anti-stripping high alumina bricks

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder after granulating and powdering processes, mixed in a certain proportion, pressed into shape, and fir··· -

silica hot repair refractory

Performance index of silica hot repair refractoryThe material is a kind of plastic unshaped refractory material, its main component is SiO2, it is made of special clinker and various binders and additives, and it is proc···