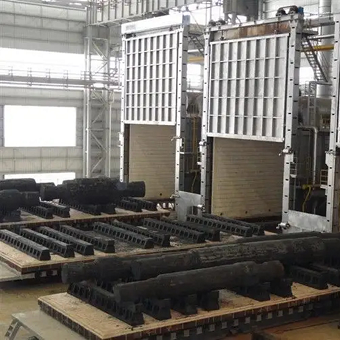

Heating refractory kilns lining and repair

Forging heating refractory kilns are very common in the thermal forging industry or are used in steel rolling production units. The purpose of the heating refractory kiln is to send large castings into the refractory kiln for decarburization heating or oxidation heating. Use an air hammer to change its shape, that is, heat it to the point where it plasticizes without melting. The castings are then taken out of the refractory kiln for forging.

The refractory materials used in the heating refractory kiln mainly include three types of products: unshaped refractory castables, high-alumina bricks, and thermal insulation materials. This time, our company mainly repairs the roof of the heating refractory kiln for customers, and the repair materials are low-cement series. This heating refractory kiln has been used continuously for many years. Originally, the refractory kiln body was mainly made of high-alumina bricks, and the refractory kiln wall, vaulted top, refractory kiln bottom, etc. were built. After many years of use, the refractory kiln top has high alumina The bricks have been burnt out and disintegrated, forming relatively large brick joints. Therefore, the purpose of this repair is to fill and level the high alumina brick surface of the refractory kiln top with refractory castables.

The use of heating refractory kiln castables to repair the original high-alumina brick roof has been maturely applied to many kinds of heating refractory kilns. The secondary protection layer, this aspect is quick and easy and suitable for emergency repairs and emergency repair work.

-

Thermal storage alumina balls

The Thermal storage alumina ballsis made of industrial alumina and refractory kaolin as the main raw materials through scientific formula, forming and high-temperature calcination.Thermal storage alumina ballss are divid··· -

Anti-stripping high alumina brick

Use description of Anti-stripping high alumina brick1. Anti-stripping high alumina brick has a good application in low temperature parts such as large and medium-sized cement precalciner, kiln smoke chamber, indoor decom··· -

Anti-stripping high alumina bricks

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder after granulating and powdering processes, mixed in a certain proportion, pressed into shape, and fir··· -

silica hot repair refractory

Performance index of silica hot repair refractoryThe material is a kind of plastic unshaped refractory material, its main component is SiO2, it is made of special clinker and various binders and additives, and it is proc···