Application fields of magnesia refractory chrome brick

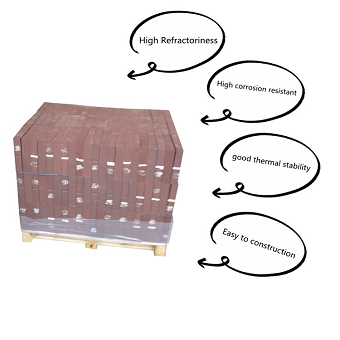

Magnesia refractory chrome brick is a basic refractory product, generally produced from sintered magnesia (with MgO content between 89% and 92%) and chrome ore as raw materials. Ordinary sintered magnesia refractory chrome brick: the purity of raw materials is not high, light-burned magnesia is used, and the sintering temperature is low.

Directly combined with magnesia refractory chrome brick: the raw materials are of high purity, using dead-burned magnesia, and the sintering temperature of bricks in tunnel kilns is higher than that of ordinary sintered magnesia refractory chrome brick;

Fused semi-recombined magnesia refractory chrome brick: the raw materials are dead-burned magnesia and fused magnesia, and the sintering temperature is higher than that of ordinary sintered magnesia refractory chrome brick;

Fused magnesia refractory chrome brick: the raw material is made of fused magnesia, and the cost is high;

Salt-immersed magnesia refractory chrome brick: In order to reduce the pores of magnesia refractory chrome brick, it is difficult for a metal solution to enter the interior of magnesia refractory chrome brick, block open pores, and prolong the service life of magnesia refractory chrome brick. After vacuum dipping, the magnesia refractory chrome brick is soaked in molten industrial sodium chloride and potassium chloride salt;

Magnesia refractory chrome bricks are mainly crystalline phases of periclase and magnesia-chrome spinel, which are fired at 1600-1800°C in an oxidizing atmosphere, and can also be made of non-fired bricks with chemical binders such as water glass.

Magnesia refractory chrome brick application fields

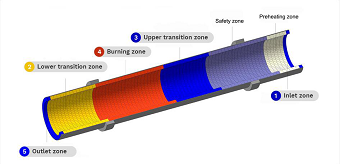

Mainly used in cement rotary kiln, glass kiln regenerator, steelmaking furnace lining, refining ladle permanent layer, non-ferrous metallurgical furnace, lime kiln, iron mixing furnace, and refractory high-temperature furnace lining, etc.

Specifications of magnesia chrome brick

Brands | Chemical Composition % | Bulk Density g/cm3 | AP % | CCS MPa | RUL℃ | Thermal Expansion (1000℃) % | TSR (1100℃water) | ||

MgO | SiO2 | Cr2O3 | |||||||

Common Magnesia Chrome Brick | |||||||||

MGe-20 | ≥40 | ≥20 | ≤22 | ≥30 | ≥1550 | ||||

MGe-16 | ≥45 | ≥16 | ≤22 | ≥30 | ≥1550 | ||||

MGe-12 | ≥55 | ≥16 | ≤22 | ≥35 | ≥1550 | ||||

MGe-8 | ≥60 | ≥8 | ≤21 | ≥35 | ≥1530 | ||||

Direct Bonded Mag-Cr Brick | |||||||||

DMC-8A | ≥80 | ≤1.0 | ≥8 | ≥3.0 | ≤17 | ≥45 | ≥1700 | ≤1.8 | ≥6 |

DMC-9A | ≥70 | ≤2.8 | ≥9 | ≥2.98 | ≤19 | ≥40 | ≥1700 | ≤1.7 | ≥6 |

DMC-12A | ≥73 | ≤1.5 | ≥12 | ≤17 | ≥45 | ≥1700 | ≤1.7 | ≥6 | |

DMC-16A | ≥70 | ≤1.5 | ≥16 | ≤18 | ≥40 | ≥1700 | ≤1.6 | ≥6 | |

Magnesia Chrome Brick | |||||||||

MGe-20 | ≥42 | ≥20 | ≤21 | ≥30 | ≥1580 | ≥8 | |||

MGe-25 | ≥38 | ≥25 | ≤22 | ≥30 | ≥1590 | ≥8 | |||

MGe-30 | ≥35 | ≥30 | ≤22 | ≥30 | ≥1610 | ≥8 | |||

-

Thermal storage alumina balls

The Thermal storage alumina ballsis made of industrial alumina and refractory kaolin as the main raw materials through scientific formula, forming and high-temperature calcination.Thermal storage alumina ballss are divid··· -

Anti-stripping high alumina brick

Use description of Anti-stripping high alumina brick1. Anti-stripping high alumina brick has a good application in low temperature parts such as large and medium-sized cement precalciner, kiln smoke chamber, indoor decom··· -

Anti-stripping high alumina bricks

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder after granulating and powdering processes, mixed in a certain proportion, pressed into shape, and fir··· -

silica hot repair refractory

Performance index of silica hot repair refractoryThe material is a kind of plastic unshaped refractory material, its main component is SiO2, it is made of special clinker and various binders and additives, and it is proc···