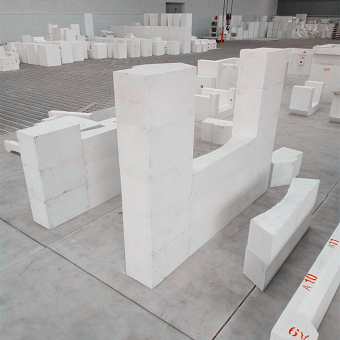

Abnormal erosion phenomenon of pool wall of fused cast AZS brick in glass furnace

1. Viscosity and temperature of glass liquid

The higher the furnace temperature, the lower the viscosity of the glass liquid. The high process temperature of the glass furnace is required by factors (such as oxy-fuel combustion technology, ultra-white glass, etc.). Properly increasing the glass melting temperature can increase the melting rate, reduce the viscosity of the glass liquid, and facilitate the discharge of bubbles. Reducing the viscosity of the glass liquid is beneficial to the improvement of the glass quality, but it is unfavorable for the corrosion resistance of the pool wall bricks, which is mainly manifested in the erosion of the gaps of the pool wall bricks, which is an abnormal erosion. Low viscosity, easy for glass liquid.

When entering the fused cast AZS brick joint, the glass phase of the brick is accompanied by the precipitation of bubbles. The upward movement of the bubbles and the mechanical movement of the glass liquid backflow generates more friction in the brick joint, which is the root cause of the abnormal erosion of the brick joint. Small is better.

2. Abnormal erosion of vertical joints in pool walls

When the kiln is running, the molten glass will seep into the cracks of the bricks exceeding the standard. In this environment, the simultaneous upward mechanical movement of the glass liquid in the brick joints, the glass phase, and bubbles precipitated in the brick joints cause the aggravated erosion of the brick joints, and the flow of the glass liquid has a backflow effect at the gaps. The backflow is a scouring process of mechanical flow, which will make the brick gap larger and larger, which is one of the abnormal erosion states.

3. Abnormal erosion at the liquid surface line of the pool wall bricks

When the glass phase content of the product is large, the poor quality of the product contains a large number of impurities, the glass phase seriously exceeds the standard, and its sodium content will reach more than 2%. When the kiln is running, a large amount of glass phase is precipitated. Due to the frictional movement of the liquid, a large amount of glass phase is precipitated on one side and taken away by the flow of glass on the other side. The erosion speed of the three-phase junction is very fast. Some of the kilns designed for 5 years will erode the upper 300mm part of the tank wall in less than 2 years. . This is a typical abnormal erosion phenomenon. Other erosion factors have been reported in a large number of literature and will not be repeated here.

4. Vertical seam erosion phenomenon of kiln sill bricks

When the kiln brick is deformed by the impact of the glass liquid, the phenomenon of widening the gap will occur at the connection between the brick and the brick. The widened gap provides the existing space for the glass liquid, and the upward movement friction of the glass phase with the liquid glass when the bubbles are precipitated leads to abnormal erosion of the kiln brick, showing a jagged shape.

5. Erosion factors of drilling holes in the pool wall

(1) When there is foreign matter iron brazing in the product, iron is one of the harmful substances and should be strictly controlled. The iron itself contains more than 2% carbon content, which will aggravate the erosion of products and is also one of the harmful substances that affect the quality of glass products.

(2) There is a phenomenon of sand inclusion in the product, and it is concentrated.

(3) When the oxygen outlet hole of the oxygen lance is blocked and cannot be uniformly oxidized, the amount of carburization in the product is high. When the gap is encountered, the bubbles are precipitated with the glass phase, which aggravates the local abnormal erosion of the product.

(4) When the cross-edge cracks or local cracks of the product and a large amount of carburization converge, the backflow of the glass liquid, the excessive glass phase content, and the precipitation of a large amount of glass phase accompanied by bubbles, or even a glass melt leakage accident.

-

Thermal storage alumina balls

The Thermal storage alumina ballsis made of industrial alumina and refractory kaolin as the main raw materials through scientific formula, forming and high-temperature calcination.Thermal storage alumina ballss are divid··· -

Anti-stripping high alumina brick

Use description of Anti-stripping high alumina brick1. Anti-stripping high alumina brick has a good application in low temperature parts such as large and medium-sized cement precalciner, kiln smoke chamber, indoor decom··· -

Anti-stripping high alumina bricks

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder after granulating and powdering processes, mixed in a certain proportion, pressed into shape, and fir··· -

silica hot repair refractory

Performance index of silica hot repair refractoryThe material is a kind of plastic unshaped refractory material, its main component is SiO2, it is made of special clinker and various binders and additives, and it is proc···