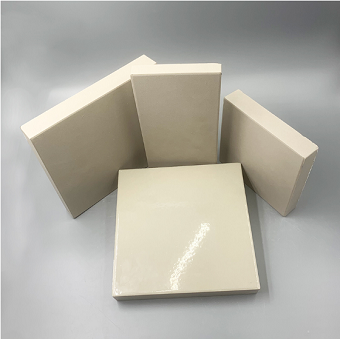

Which areas are acid-proof bricks mainly used for?

Acid-proof bricks have always been a special building material, and cannot be replaced by other products due to the particularity of the use environment. Especially the oxidation tank and reaction tank in the chemical industry have extremely high requirements for acid and alkali resistance, and acid-proof bricks are generally used. If it is replaced with ordinary tiles, it will be in disrepair for a long time, resulting in corrosion of the tank body. During the oxidation or reaction process, the strong corrosiveness may cause the liquid leakage of the reaction tank. In the event of casualties, chemical companies must pay attention when selecting materials for decoration, and cannot cause serious consequences for temporary benefits.

Which areas are acid-proof bricks mainly used for?

1. In the smelting industry, acid-proof bricks are mainly used to make crucibles for metallurgical metals, precious metals, and rare metals; in the steelmaking industry, acid-proof bricks are used as ingot protectors, and acid-proof bricks are used to make magnesia-carbon bricks for steelmaking furnaces. Furnace lining and carbon filler, etc. The furnace age of the acid-resistant brick crucible is related to the crystallinity of the acid-resistant brick. 80 mesh and 50 mesh (0.3 ~ 0.18 mm) acid-proof bricks are generally used in the manufacture of crucibles for the above reasons.

2. As the conductive material

Acid-proof bricks are widely used in the electrical industry as electrodes, brushes, carbon rods, acid-resistant brick pads, acid-resistant brick rings, electroactive parts, coatings for movie picture tubes, etc. Among them, acid-resistant brick electrodes are widely used. acid-proof bricks used in the electrical industry have very, very high requirements for particle size. The particle size control is in the range of 150-325 mesh, (0.1-0.42mm), while the acid-proof bricks practical for film imaging require the particle size of acid-proof bricks to be below 0.5 microns. The fixed carbon content is required to be in the range of 60 to 999%, the content of harmful impurities is required to be below 1%, and the content of harmful impurities in the paint of color TV picture tubes is required to be below 5ppm.

3. As wear-resistant and lubricating material

acid-proof bricks are used as wear-resistant materials and lubricants in the machinery industry. acid-proof bricks as wear-resistant materials can slide at a speed of 100 m/s in the temperature range of -200 to 2000 °C without lubricating oil. The acid-resistant brick emulsion is also a good lubricant for many, many metal polishing (drawing, pipe drawing).

4. As a sealing material

Use of flexible acid-proof bricks as piston rings and sealing rings should be used in centrifugal pumps, marine turbines, water turbines, and facilities for conveying erosive media, etc.

5. For sand casting, forging, pressing, and high-temperature smelting materials

acid-proof bricks can be used as casting molds for glassware, gray smelting castings, powder smelting pressure molding, high-temperature internal resistance furnace tubes, etc.

6. As corrosion-resistant material

acid-proof bricks are often used to supervise the production of boiling water exchangers, contrast tanks, condensers, combustion towers, absorption towers, coolers, refiners, purifiers, and other facilities, and are widely used in petroleum, chemical, hydrometallurgy, acid, and alkali production. , synthetic fiber, paper, and other industrial sectors can save a lot of metal.

7. Application of orchard energy and coastal defense industry

acid-proof bricks are one of the key structural materials for the construction of nuclear-backed reactors, which are used as shielding materials and reflective materials. acid-proof bricks are also used as neutron moderators in orchards. In the coastal defense industry, acid-proof bricks are used as solid oil materials, rocket nozzles, missile nose cones, aerospace facilities components, thermal insulation materials, radiation protection materials, etc.

8, as oil

Cryptocrystalline low-carbon acid-proof bricks can be used for combustion for micro ovens, industrial pots, bricks, civil honeycomb, etc.

9. As anti-scaling, anti-rust material, cast steel cold welding material

acid-proof bricks can prevent pot scales from scaling, metal rusting, and carbon filling for cold welding of cast steel.

10. Other functions

acid-proof bricks can be used as pencil leads, dyes, polishes, fertilizer catalysts, sheet carbon rods, glass coolants, etc.

-

Thermal storage alumina balls

The Thermal storage alumina ballsis made of industrial alumina and refractory kaolin as the main raw materials through scientific formula, forming and high-temperature calcination.Thermal storage alumina ballss are divid··· -

Anti-stripping high alumina brick

Use description of Anti-stripping high alumina brick1. Anti-stripping high alumina brick has a good application in low temperature parts such as large and medium-sized cement precalciner, kiln smoke chamber, indoor decom··· -

Anti-stripping high alumina bricks

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder after granulating and powdering processes, mixed in a certain proportion, pressed into shape, and fir··· -

silica hot repair refractory

Performance index of silica hot repair refractoryThe material is a kind of plastic unshaped refractory material, its main component is SiO2, it is made of special clinker and various binders and additives, and it is proc···