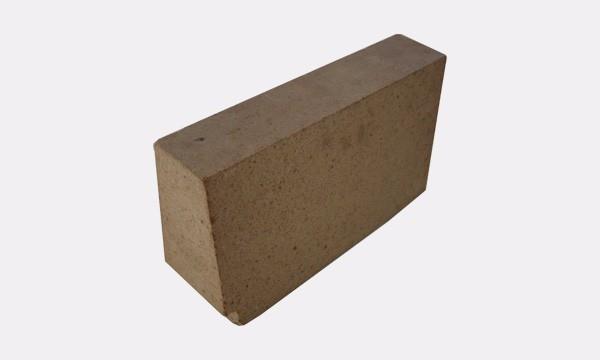

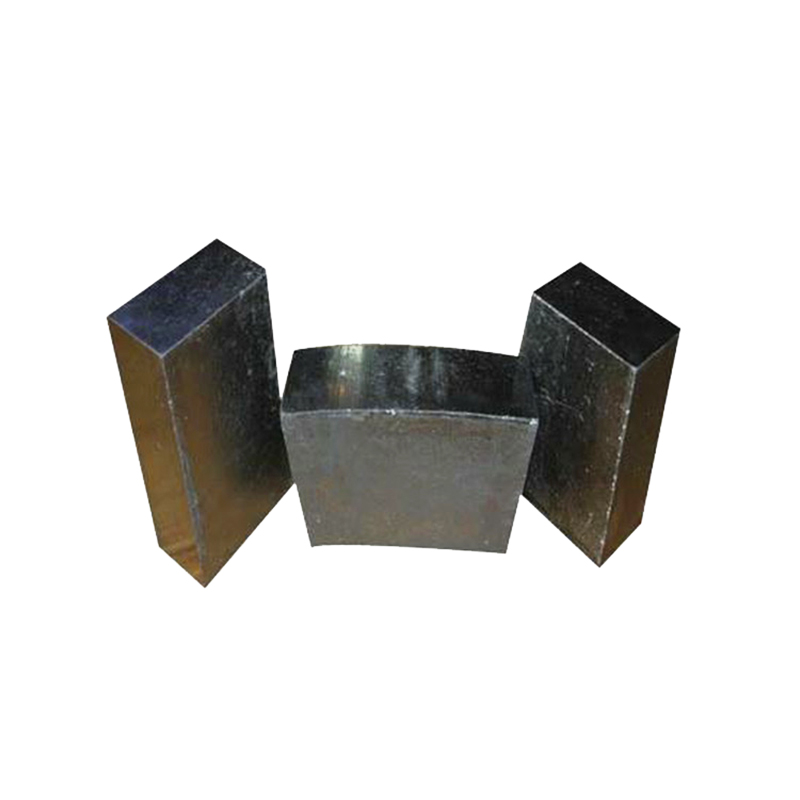

Refractory magnesia carbon brick black for ladle and refining furnace

Model Number:

Certification:

Minimum Order Quantity:

Refractory magnesia carbon brick black for ladle and refining furnace

Magnesia carbon brick is a high-melting-point alkaline oxide magnesia and a high melting point carbon material which is hard to be invaded by slag as a raw material, and various non-oxide additives are added. Magnesia carbon brick is a non-burning carbon composite refractory material which is combined with carbon binder.

Magnesia-carbon bricks are made of heavy-burned magnesia (or fused magnesia) and carbon materials (mainly crystallized graphite), and are pressed together with resin as a bonding material.

Magnesium carbon brick forms magnesium skeleton when used at high temperature. Because magnesium oxide and carbon do not produce mutual solubility relationship, the excellent fire resistance of the original component is retained, and the thermal conductivity of carbon is good, and the thermal expansion coefficient and elastic modulus are low , and it can effectively prevent high temperature spalling and slag penetration, so that structural spalling does not occur, greatly changing the fatal weakness of the metamorphic structure caused by the slag penetration of the magnesia refractory material, combined with the non-wetting property of carbon to the slag, and the corrosion resistance is very good.

This series of characteristics of magnesia carbon bricks makes it an ideal charge material for thermal shock resistance, erosion resistance and peeling resistance. Magnesia carbon bricks are widely used and can be used in key parts of thermal equipment such as steelmaking converters, electric arc furnaces, steel drums, and furnace refining furnaces.

We have added a vast variety of Magnesium Carbon Bricks, which is manufactured using fused magnesia or burned magnesia in crystallite size. Manufactured under the guidance of sedulous professionals, our bricks are ensured for performing under higher pressure.

Also, these products have antioxidant material and are acclaimed for possessing the following quality attributes:

1.Excellent corrosion resistance

2.High resistance to spalling

3.Free from dust particles

4.Optimum performance

Physical and chemical Indicators of magnesia carbon brick:

| Item |

MC- 10A |

MC- 10B |

MC- 10C |

MC- 14A |

MC- 14B |

MC- 14C |

MC-1 8A |

MC- 18B |

MC- 18C |

|

MgO/% ≥ |

80 |

78 |

76 |

76 |

74 |

74 |

72 |

70 |

70 |

|

C/% ≥ |

10 |

10 |

10 |

14 |

14 |

14 |

18 |

18 |

18 |

|

Apparent porosity/% ≤ |

4 |

5 |

6 |

4 |

5 |

6 |

3 |

4 |

5 |

|

Bulk density/g.cm3 ≥ |

2.9 |

2.85 |

2.8 |

2.9 |

2.82 |

2.77 |

2.9 |

2.8 |

2.77 |

|

Cold crushing strength/ Mpa ≥ |

40 |

35 |

30 |

40 |

35 |

25 |

40 |

35 |

25 |

|

Modulus of rupture/Mpa ≥ |

6 |

5 |

4 |

10 |

8 |

5 |

9 |

7 |

4 |

The technical data pertains to machine pressed standard bricks in compliance with the testing standard. These data are typical approximate guide value. Not to be construed as a binding specification.

Size tolerance ±1.% or 1.5mm whichever is greater.

Magnesia Carbon Bricks with properties of higher values available where applications require the same.

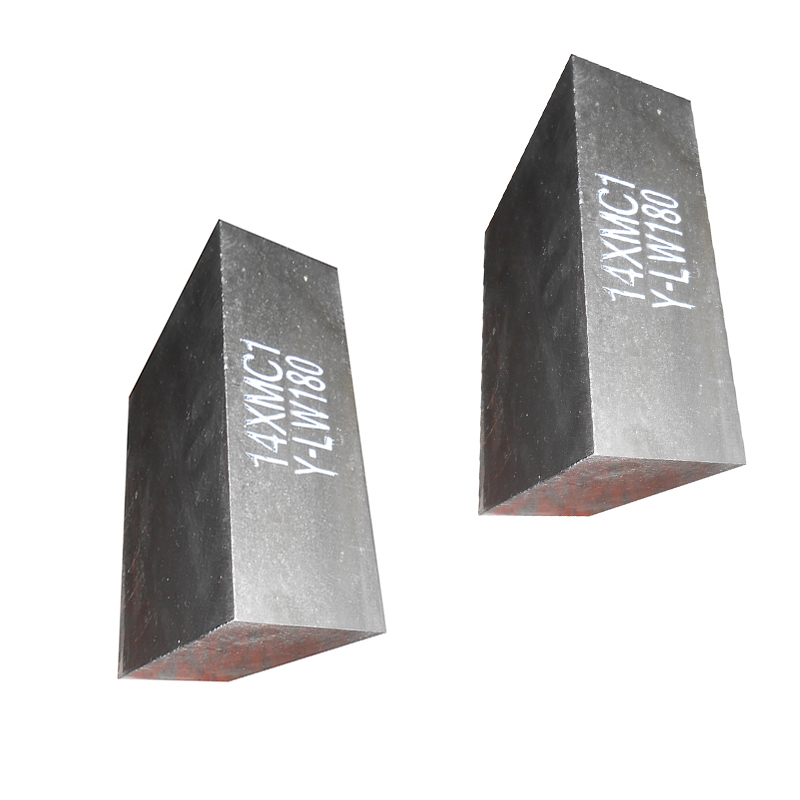

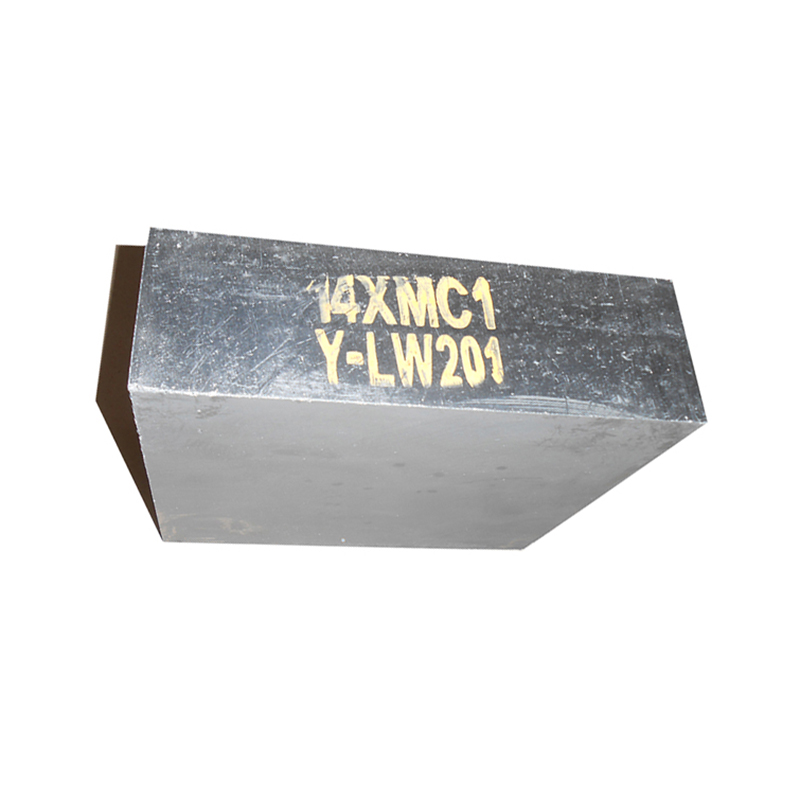

Shapes &Sizes of our magnesia carbon brick

| Straight |

Split |

Arch |

Wedge |

Tile |

Other Shape |

|

L×W×H(mm) 230×114×65 230×114×75 |

L×W×H (mm) 230×114×25 230×114×32 230×114×37 230×114×50 |

L×W×H/h(mm) 230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65 |

L×W×H/h (mm) 230×114×65/45 230×114×65/55 220×114×75/45 220×114×75/55 220×114×75/65 |

L×W×H (mm) 230×230×38 230×230×50 230×230×65 230×230×75 |

Key brick, Skew brick, Soap, Checker, Neck, Taper, |

|

We also can make brick according to customers' drawing and requirements. |

|||||

1.High strength under high temperature

2.High erosion resistance and wearing proof

3.Good thermal shock resistance

4.Good heating ability

5.Durable

6.Stable product quality, all the Slide Gate Series products can meet the national standards

7.A long service life in actual use and good reputation

8.Can meet different casting conditions.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..