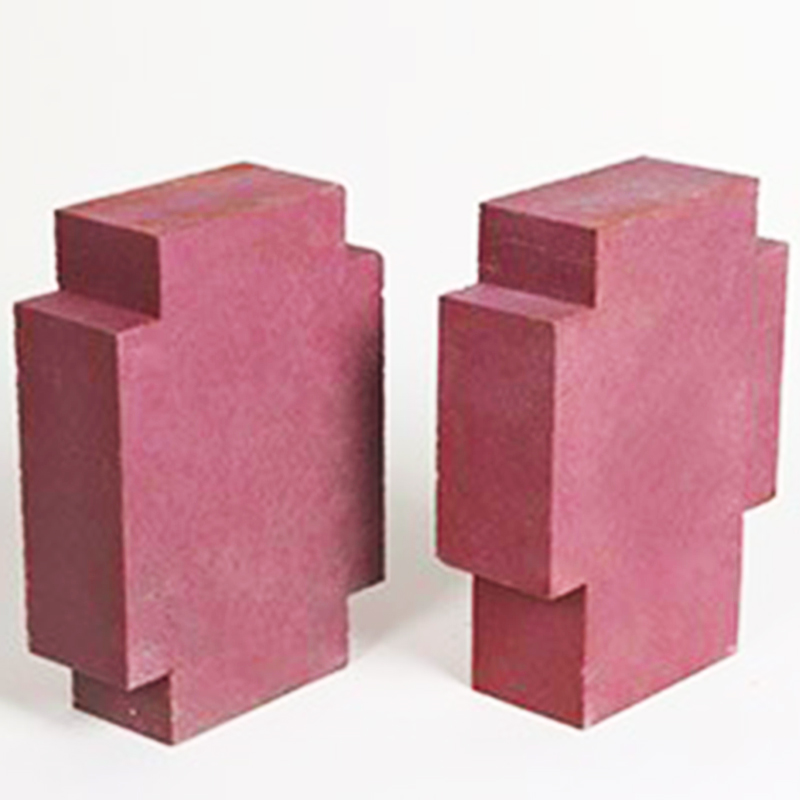

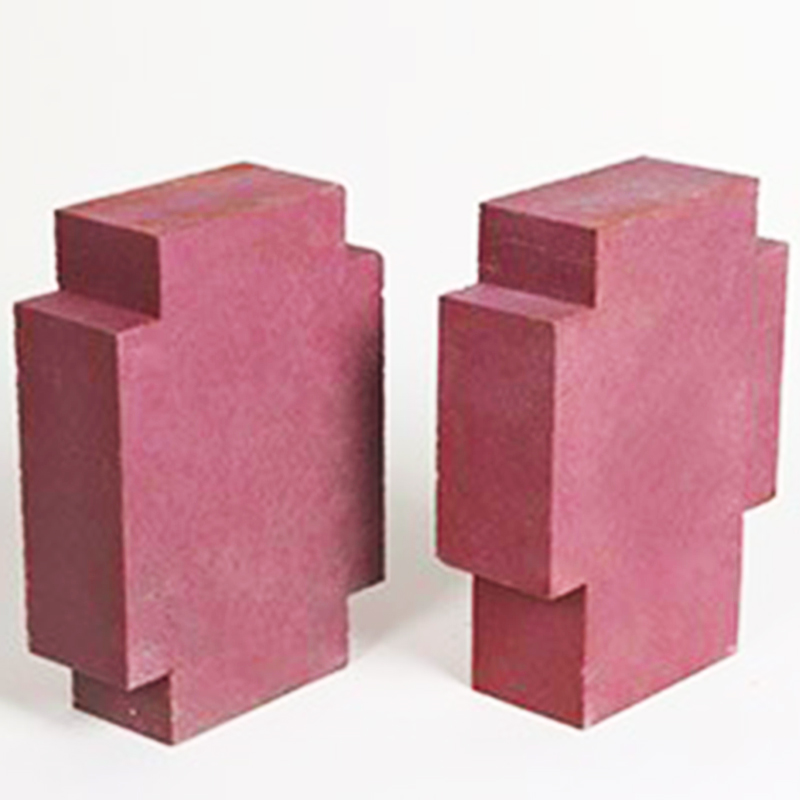

Good wear resistance Chrome-Corundum brick

Model Number:

Certification:

Minimum Order Quantity:

Good wear resistance Chrome-Corundum brick

Chrome corundum brick is pure Al2O3 and Cr2O3 as the main raw material synthesis compared with pure corundum brick it has better performance such as refractoriness load softening deformation temperature bending strength high temperature creep high temperature volumetric stability And resistance to slag corrosion.

Chrome corundum Bricks is produced with high quality of sintered corundum synthetic mullite and chromium oxide as raw material and processed under high temperature and high pressure. They have high bulk density high compressive strength good thermal shock resistance good corrosion resistance to acid and alkali. The bricks are not affected by H2 CO gase.

Advantages:

1.high density porosity

2.Low bulk density

3.Good crush resistant

4.Good thermal resistant

5.Long using time

6.Resistance to metal melt

7.Good resistance to slag corrosive

|

Item |

chrome20 |

chrome60A |

chrome60B |

|

Cr2O3 % |

20 |

>60 |

>60 |

|

Al2O3 % |

60 |

16 |

16 |

|

ZrO2% |

/ |

11 | 11 |

|

Bulk Density g/cm3 |

>3.70 |

>3.85 |

>3.70 |

|

Cold compressive strength Mpa |

120 |

>200 |

>100 |

|

Apparent porosity |

<18 |

<14 |

<18 |

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..