Thermal Shock Resistance Zero Thermal Expansion Silica Brick for Coke Oven Hot Repair

Model Number:

Certification:

Minimum Order Quantity:

Thermal Shock Resistance Zero Thermal Expansion Silica Brick for Coke Oven Hot Repair

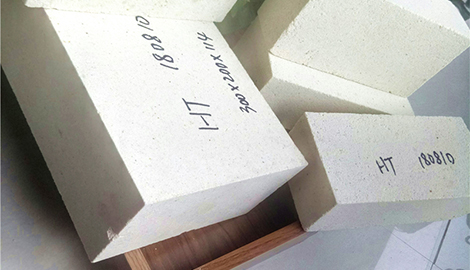

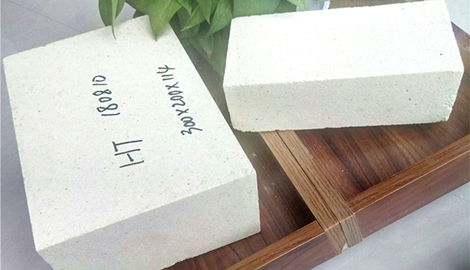

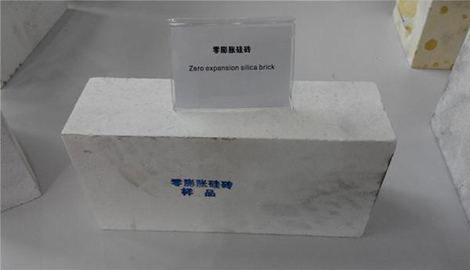

Zero thermal expansion silica brick is also known as fused-quartz brick or thermal shock resistance silica brick. The main raw materials are amorphous fused silica and the thermal expansion coefficient is near zero, so the product is named zero thermal expansion silica brick.

Advantages Of zero thermal expansion silica brick

1.Longer service life, accurate size tolerance, pure color, luster appearance.

2.Excellent thermal shock resistance.

3.Good structural strength at high temperature.

4.Zero thermal expansion rate

5.Without crack and peeling phenomena.

Technical data of zero thermal expansion silica brick

Thermal Shock Resistance Zero Thermal Expansion Silica Brick for Coke Oven Hot Repair

Applications Of Zero Thermal Expansion Silica Brick

1. It is widely used in hot repair project on coke oven.

2. Coke oven maintenance time shortens greatly. Ensure the quality of coke oven repair. Improve the production of coke oven.

3. CUNSE is not only providing the hot repair method of coke oven, but also contracting for coke oven maintenance.

Zero Thermal Expansion Silica Brick Size

|

Straight Type |

Arch Type |

Wedge Type |

|

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

|

Other Sizes Can Be Customized |

||

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..