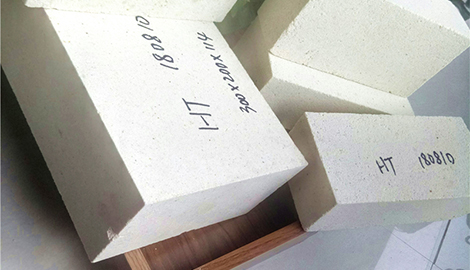

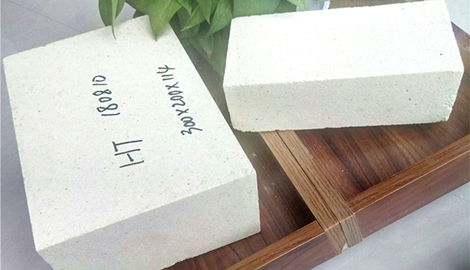

China Hot Blast Stove Silica Checker Refractory Brick

Model Number:

Certification:

Minimum Order Quantity:

A brief introduction of silica brick

Silica brick is a kind of acid refractory mainly made from tridymite, cristobalite and a small amount of residual quartz as well as glass phase. The raw material is natural silica sand whose SiO2 content should be more than 96%. The higher SiO2 content in silica sand, the higher temperature silica bricks resist. Silica bricks are used in the roof and superstructure of glass melting tanks as well as for hot repairs.

Our silica brick advantages

--Adopts high quality silica and advanced technology, our silica bricks enjoy the advantages of high purity, long service life, good thermal conductivity, high refractoriness under load, and good creep resistance.

--In addition, it has accurate size tolerance, pure color and luster appearance.

--Because of the good thermal shock resistance of silica brick, it is mainly used in the continuous operating furnace.

--Supporting the use of other high quality refractories, our silica brick can extent the service life of float glass furnace to 8 years and double the service life of bottle glass furnace.

Specifications Of Silica Brick

1.Higher SiO2 content of more than 96%, with true density of 2.34g/cm3, thus it has good performance in corrosion of acid slag.

2.Excellent resistance in high temperature. The melting temperature under load is 1620-1670℃. Durable, with no deformation under high temperature.

3.Good thermal shock resistance, High heat conductivity.

4.At 1450℃, there is 1.5-2.2% overall expansion which makes the joint-cutting dovetailed, thus silica bricks have good air tightness and strong structure.

Technical Data Of Silica Brick

|

ndex |

High quality Silica Bricks |

Silica Bricks for coke oven |

|||||

|

XBG-96 |

ZBG-96 |

DBG-96 |

JG-94A |

JG-94B |

JG-94Y |

||

|

15Kgs |

15-25Kgs |

25-40Kgs |

|||||

|

Refractoriness |

1690 |

1690 |

1690 |

||||

|

Apparent porosity % |

22 |

23 |

24 |

22 |

24 |

22 |

|

|

True density |

2.34 |

2.34 |

2.34 |

2.35 |

2.35 |

2.35 |

|

|

Cold crushing strength MPa |

35(30) |

35(30) |

29.4 |

29.4 |

19.6 |

29.4 |

|

|

Refractoriness under load 0.2Mpa ℃ |

1680 |

1680 |

1670 |

1650 |

1650 |

1650 |

|

|

Permanent linear change % |

0-0.3 |

0-0.3 |

0-0.3 |

0.2

|

|||

|

Index |

Silica Bricks for glass kiln |

Silica Bricks for Hot-Blast stoves |

|||||||

|

BG-95A |

BG-95B |

BG-96A |

BG-96B |

GZ-94 |

GZ-95 |

Wall of stove |

Check brick |

||

|

Refractoriness |

1710 |

1710 |

|||||||

|

True density |

2.34 |

2.34 |

2.35 |

2.35 |

2.38 |

2.37 |

2.35 |

2.35 |

|

|

Apparent porosity % |

22(24) |

22(24) |

22(24) |

22(24) |

23 |

22 |

22 |

23 |

|

|

Cold crushing strength MPa |

35(30) |

35(30) |

35(30) |

35(30) |

24.5 |

29.4 |

35 |

30 |

|

|

Refractoriness under load 0.2Mpa ℃ |

1660 |

1650 |

1680 |

1670 |

1640 |

1650 |

|||

|

Melting index% ≤ |

0.7(0.7) |

0.5(0.6) |

|||||||

|

Creep 0.2Mpa50h % |

15500.8 |

15500.8 |

|||||||

|

Thermal shock resistance at 1000℃ % |

1.26 |

1.26 |

|||||||

|

Remain quartz % |

Data must be provided |

||||||||

|

Chemical |

SiO2 % |

95 |

95 |

96 |

96 |

94 |

94 |

95 |

95 |

|

Fe2O3 % |

1.0 |

1.0 |

0.8 |

1.0 |

|||||

China Hot Blast Stove Silica Checker Refractory Brick Supplier

Applications Of Silica Brick

The silica brick can be widely used in coke oven, hot blast furnace, glass furnace and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown, suspended wall of channel, top crown and inlet sealing. In detail, silica bricks plays the following role in different fields:

--being the partition walls in coke oven carbonization and burning chamber;

--metallurgy industry: used as refractories for steel making open hearth regenerator, slag pocket, soaking pit;

--arch crown and other weight bearing areas in ceramic kilns, hot blast furnace and acid open hearth;

--worked as building checker chamber, chute, combustion chamber, coking chamber and furnace arch in glass melting furnaces.

Refractory Silica Bricks Size

|

Straight Type |

Arch Type |

Wedge Type |

|

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

|

Other Sizes Can Be Customized |

||

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..