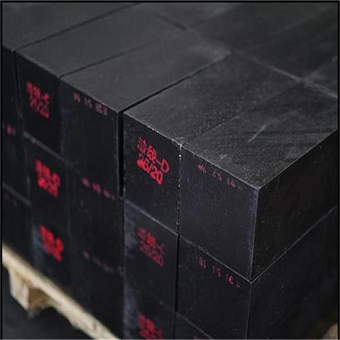

The characteristics of refractory magnesia carbon bricks

The experience of using magnesia-carbon bricks in converters, electric furnaces and ladle shows that because of their excellent high-temperature resistance. At present, magnesia-carbon bricks show the disadvantages of high-priced graphite consumption, increased heat consumption, and continuous increase of carbon into molten steel, thereby polluting molten steel. In order to reduce the cost of raw materials and pure molten steel, low-carbon magnesia-carbon bricks with Low carbonization can solve these problems very well.

The characteristics of magnesia carbon bricks are mainly reflected in the following aspects

1. Microstructure density of magnesia carbon bricks

The compactness of the magnesia-carbon brick depends on the type and amount of binder and antioxidant, the type of magnesia, the particle size and amount of graphite, etc. In addition, molding equipment, brick pressing technology, and heat treatment conditions have certain influences. magnesia-carbon bricks with a particle size of less than 1mm are used in wind eye bricks and tapping bricks. Different binders also have a certain influence on the compactness of magnesia-carbon bricks, and the binder with a high carbon residue rate is selected for its higher bulk density. The effect of adding different antioxidants on the compactness of magnesia-carbon bricks is obviously different. The heating speed of magnesia-carbon bricks during use will also affect the change of its apparent porosity.

2. High-temperature performance of magnesia carbon bricks

2.1 Research shows that for high-temperature flexural strength above 1200 °C, no additives < calcium boride < aluminum < aluminum-magnesium < aluminum + boride Calcium < aluminum magnesium + calcium boride, where aluminum magnesium + boron carbide is between aluminum magnesium and aluminum magnesium + calcium boride.

-

Thermal storage alumina balls

The Thermal storage alumina ballsis made of industrial alumina and refractory kaolin as the main raw materials through scientific formula, forming and high-temperature calcination.Thermal storage alumina ballss are divid··· -

Anti-stripping high alumina brick

Use description of Anti-stripping high alumina brick1. Anti-stripping high alumina brick has a good application in low temperature parts such as large and medium-sized cement precalciner, kiln smoke chamber, indoor decom··· -

Anti-stripping high alumina bricks

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder after granulating and powdering processes, mixed in a certain proportion, pressed into shape, and fir··· -

silica hot repair refractory

Performance index of silica hot repair refractoryThe material is a kind of plastic unshaped refractory material, its main component is SiO2, it is made of special clinker and various binders and additives, and it is proc···