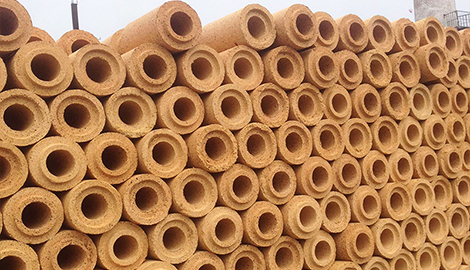

sk36 sk38 high alumina brick

Model Number:

Certification:

Minimum Order Quantity:

We are one of the reliable refractory bricks Manufacturers in China. We offer an exclusive range of refractory bricks which are of optimum quality. Our range encompasses of refractory bricks, High Alumina Low Ferric Fire Bricks etc which are highly exclusive. We offer different shapes and sizes in our High Alumina Bricks which cannot be availed through anywhere else. We use the best quality material to manufacture our refractory bricks so that there is no compromise in their quality. We offer our refractory bricks at quite reasonable prices and also deliver them well within the stipulated time avoiding all delays.

refractory bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It(High Alumina Brick,Alumina Brick,Refractory Alumina) features excellent high temperature mechanics and chemical corrosion resistance.

Standard Size Sk36 Refractory Brick Feature

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Standard Size Sk36 Refractory Brick

| Items |

Technical Data |

||||

|

International code name |

SK35 |

SK36 |

SK37 |

SK38 |

SK40 |

|

Chinese code name |

LZ-48 |

LZ-55 |

LZ-65 |

LZ-75 |

LZ-80 |

|

Al2O3 min % |

48 |

55 |

65 |

75 |

80 |

|

Fe2O3 max % |

2 |

2 |

2 |

2 |

2 |

|

Refractoriness oC min. |

1750 |

1770 |

1790 |

1790 |

1790 |

|

Refractoriness under Load C min. |

1420 |

1470 |

1500 |

1520 |

1530 |

|

Permanent Linear Change % |

1450 C×2h |

1500 C×2h |

1500 C×2h |

1500 C×2h |

1500 C×2h |

|

+0.1~-0.4 |

+0.1~-0.4 |

+0.1~-0.4 |

+0.1~-0.4 |

+0.1~-0.4 |

|

|

Apparent Porosity max. % |

22 |

22 |

23 |

23 |

21 |

|

Cold Crushing Strength mim. |

39 |

44 |

49 |

54 |

65 |

Note :

Size Tolerance : + / - 1.5 % or + / - 2 Mm Which Ever is Greater

Above Specified Values Relate to Machine Pressed Standard Bricks.

P L C Values are for Specimens Heated At Given Temp. for 2 Hours

Standard Size Sk36 Refractory Brick

refractory bricks Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..